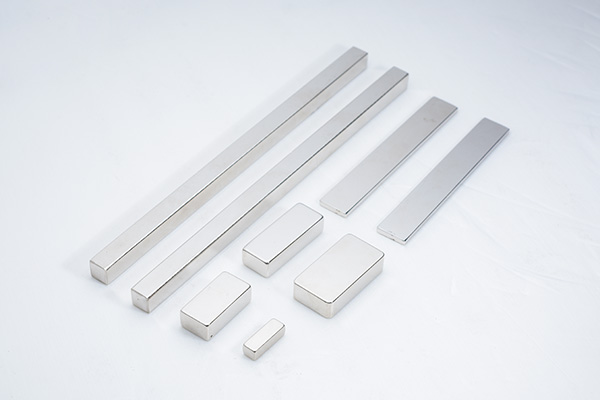

Square magnet

Origin: China

Model:

You can through the customer service hotline, consulting product information

Description

Sintered NdFeB permanent magnet material has excellent magnetic performance, widely used in electronics, power machinery, medical equipment, toys, packaging, hardware machinery, aerospace and other fields, the more common permanent magnet motor, speakers, magnetic separator, computer disk drive, magnetic resonance imaging equipment and instruments, etc. Welcome to provide your drawings and specifications to manufacture custom magnets

Magnetic performance table

| Grade | Remanence(Br) | Coercivity(bHc) | Intrinic Coercivity | Max Energy Product | Working Temperature Tw ℃ | ||||

| (iHc) | (BH)max | ||||||||

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ||

| N35 | 1.18-1.23 | 11.8-12.3 | ≥860 | ≥10.8 | ≥955 | ≥12 | 263-287 | 33-36 | ≤80 |

| N38 | 1.22-1.28 | 12.2-12.8 | ≥860 | ≥10.8 | ≥955 | ≥12 | 287-310 | 36-39 | ≤80 |

| N40 | 1.26-1.31 | 12.6-13.1 | ≥876 | ≥11.0 | ≥955 | ≥12 | 302-326 | 38-41 | ≤80 |

| N42 | 1.28-1.34 | 12.8-13.4 | ≥876 | ≥11.0 | ≥955 | ≥12 | 318-342 | 40-43 | ≤80 |

| N45 | 1.32-1.37 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | ≤80 |

| N48 | 1.36-1.42 | 13.6-14.2 | ≥876 | ≥11.0 | ≥955 | ≥12 | 358-390 | 45-48 | ≤80 |

| N50 | 1.39-1.45 | 13.9-14.5 | ≥876 | ≥11.0 | ≥955 | ≥12 | 374-406 | 47-51 | ≤80 |

| N52 | 1.42-1.48 | 14.2-14.8 | ≥796 | ≥10.0 | ≥876 | ≥11 | 390-422 | 49-53 | ≤80 |

| N54 | 1.45-1.51 | 14.5-15.1 | ≥756 | ≥9.5 | ≥876 | ≥11 | 400-440 | 51-55 | ≤80 |

| N35M | 1.18-1.23 | 11.8-12.3 | ≥876 | ≥11 | ≥1114 | ≥14 | 263-287 | 33-36 | ≤100 |

| N38M | 1.22-1.28 | 12.2-12.8 | ≥876 | ≥11 | ≥1114 | ≥14 | 287-310 | 36-39 | ≤100 |

| N40M | 1.26-1.31 | 12.6-13.1 | ≥876 | ≥11 | ≥1114 | ≥14 | 302-326 | 38-41 | ≤100 |

| N42M | 1.28-1.34 | 12.8-13.4 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 318-342 | 40-43 | ≤100 |

| N45M | 1.34-1.39 | 13.4-13.9 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 342-366 | 43-46 | ≤100 |

| N48M | 1.36-1.42 | 13.6-14.2 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 366-390 | 46-49 | ≤100 |

| N50M | 1.39-1.45 | 13.9-14.5 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 384-408 | 48-51 | ≤100 |

| N35H | 1.18-1.23 | 11.8-12.3 | ≥876 | ≥11 | ≥1353 | ≥17 | 263-287 | 33-36 | ≤120 |

| N38H | 1.22-1.28 | 12.2-12.8 | ≥876 | ≥11 | ≥1353 | ≥17 | 287-310 | 36-39 | ≤120 |

| N40H | 1.26-1.31 | 12.6-13.1 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | ≤120 |

| N42H | 1.28-1.34 | 12.8-13.4 | ≥955 | ≥12 | ≥1353 | ≥17 | 318-342 | 40-43 | ≤120 |

| N45H | 1.33-1.39 | 13.3-13.9 | ≥955 | ≥12 | ≥1353 | ≥17 | 342-366 | 43-46 | ≤120 |

| N48H | 1.36-1.42 | 13.6-14.2 | ≥955 | ≥12 | ≥1353 | ≥17 | 366-390 | 46-49 | ≤120 |

| N50H | 1.39-1.45 | 13.9-14.5 | ≥955 | ≥12 | ≥1274 | ≥16 | 384-408 | 48-51 | ≤120 |

| N33SH | 1.14-1.19 | 11.4-11.9 | ≥836 | ≥10.5 | ≥1592 | ≥20 | 247-270 | 31-34 | ≤150 |

| N35SH | 1.18-1.23 | 11.8-12.3 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | ≤150 |

| N38SH | 1.22-1.28 | 12.2-12.8 | ≥876 | ≥11 | ≥1592 | ≥20 | 287-310 | 36-39 | ≤150 |

| N40SH | 1.26-1.30 | 12.6-13.0 | ≥923 | ≥11.6 | ≥1592 | ≥20 | 302-326 | 38-41 | ≤150 |

| N42SH | 1.28-1.34 | 12.8-13.4 | ≥955 | ≥12 | ≥1592 | ≥20 | 318-342 | 40-43 | ≤150 |

| N45SH | 1.33-1.39 | 13.3-13.9 | ≥955 | ≥12 | ≥1592 | ≥20 | 342-366 | 43-46 | ≤150 |

| N48SH | 1.36-1.42 | 13.6-14.2 | ≥955 | ≥12 | ≥1592 | ≥20 | 366-390 | 46-49 | ≤150 |

| N28UH | 1.03-1.09 | 10.3-10.9 | ≥740 | ≥9.30 | ≥1990 | ≥25 | 207-231 | 26-29 | ≤180 |

| N30UH | 1.09-1.14 | 10.9-11.4 | ≥796 | ≥10 | ≥1990 | ≥25 | 223-247 | 28-31 | ≤180 |

| N33UH | 1.13-1.19 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1990 | ≥25 | 247-263 | 31-33 | ≤180 |

| N35UH | 1.18-1.22 | 11.8-12.2 | ≥876 | ≥11 | ≥1990 | ≥25 | 263-287 | 33-36 | ≤180 |

| N38UH | 1.22-1.27 | 12.2-12.7 | ≥876 | ≥11 | ≥1990 | ≥25 | 287-310 | 36-39 | ≤180 |

| N40UH | 1.26-1.30 | 12.6-13.0 | ≥923 | ≥11.6 | ≥1990 | ≥25 | 302-326 | 38-41 | ≤180 |

| N42UH | 1.28-1.34 | 12.8-13.4 | ≥955 | ≥12 | ≥1990 | ≥25 | 318-342 | 40-43 | ≤180 |

| N28EH | 1.03-1.09 | 10.3-10.9 | ≥740 | ≥9.30 | ≥2388 | ≥30 | 207-231 | 26-29 | ≤200 |

| N30EH | 1.08-1.13 | 10.8-11.3 | ≥796 | ≥10.0 | ≥2388 | ≥30 | 223-247 | 28-31 | ≤200 |

| N33EH | 1.13-1.19 | 11.3-11.7 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 247-263 | 31-33 | ≤200 |

| N35EH | 1.18-1.22 | 11.8-12.2 | ≥876 | ≥11 | ≥2388 | ≥30 | 263-287 | 33-36 | ≤200 |

| N38EH | 1.22-1.27 | 12.2-12.7 | ≥876 | ≥11 | ≥2388 | ≥30 | 287-310 | 36-39 | ≤200 |

| N40EH | 1.26-1.30 | 12.6-13.0 | ≥923 | ≥11.6 | ≥2388 | ≥30 | 302-326 | 38-41 | ≤200 |

| N28AH | 1.03-1.09 | 10.3-10.9 | ≥740 | ≥9.30 | ≥2786 | ≥35 | 207-231 | 26-29 | ≤220 |

| N30AH | 1.08-1.13 | 10.8-11.3 | ≥796 | ≥10.0 | ≥2786 | ≥35 | 223-247 | 28-31 | ≤220 |

| N33AH | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥2786 | ≥35 | 247-263 | 31-33 | ≤220 |

| N35AH | 1.18-1.23 | 11.8-12.3 | ≥876 | ≥11.0 | ≥2786 | ≥35 | 263-287 | 33-36 | ≤220 |

size specification

| Block products | range of sizes(mm) | size(mm) | Maximum processing accuracy | ||||

|---|---|---|---|---|---|---|---|

| L | W | T | dimensional tolerance | depth of parallelism | verticality | ||

| 1<L<=300 | 1<L<=100 | 1<L<60 |

L<=10 10<L<=60 60<L<=100 100<L<=300 |

±0.03 ±0.05 ±0.1 ±0.15 |

0.05 0.1 0.2 0.2 |

0.1 0.1 0.3 0.5 |

|

| Circle chip products | range of sizes(mm) | size(mm) | Maximum processing accuracy | |||

|---|---|---|---|---|---|---|

| D | T | dimensional tolerance | depth of parallelism | verticality | ||

| 2<OD<=300 | 1<T<60 |

OD<=10 10<OD<=60 60<OD<=100 100<OD<=300 |

±0.03 ±0.05 ±0.1 ±0.15 |

0.05 0.1 0.2 0.2 |

0.1 0.1 0.3 0.5 |

|

| arc | range of sizes(mm) | size(mm) | Maximum processing accuracy | |||||

|---|---|---|---|---|---|---|---|---|

| OD | H | W | T | dimensional tolerance | depth of parallelism | verticality | ||

| / | 2<H<=250 | 2<H<=100 | 1<T<=60 |

H<=10 10<H<=60 60<OD/ID<=100 100<OD/ID<=300 |

±0.03 ±0.05 ±0.1 ±0.15 |

0.05 0.1 0.2 0.2 |

0.1 0.1 0.3 0.5 |

|

Description of sintered NdFeB ND-Fe-B magnetic steel coating

| Coating type | Coating symbol | colour | Coating thickness (μm) | SST(h) | Operating temperature | peculiarity |

| Chromium blue white zinc trivalent | ZN | White and blue | 4—10 | 12-24 | ≤160℃ | General protection, suitable for most products |

| Chrome-colored zinc trivalent | Colored Zn | undertone | 4—10 | >24 | ≤160℃ | Salt spray resistance |

| Phosphating/passivation | Phosphated/Passivation | gray | / | 4—8 | ≤250℃ | Temporary protection |

| nickel-copper-nickel | NICUNI | silver | 10—30 | >24 | ≤200℃ | Salt spray resistance, heat and humidity resistance, high temperature resistance |

| Nickel + tin | NI+SN | silver | 10—30 | >48 | ≤160℃ | Pleasing to the eye |

| Nickel + silver | NI+AG | silver | 10—30 | >48 | - | Pleasing to the eye |

| Nickel + gold | NI+AU | golden | 10—30 | >48 | ≤200℃ | Pleasing to the eye |

| Epoxy resin | EPOXY | black | 10—30 | >24 | ≤160℃ | Super salt spray resistance, moisture and heat resistance, good insulation |

| Nickel copper + epoxy black | NICU+EPOXY | black | 20—40 | >48 | ≤160℃ | Super salt spray resistance, moisture and heat resistance, good bonding force, good insulation |

| Chemical nickel | Electroless Nickel | silver | 4-8 | >96 | ≤200℃ | Salt spray resistance, heat and humidity resistance, high temperature resistance |

| Efrow | Everlube | yellow | 8-20 | >24 | ≤200℃ | Salt spray resistance |

| Teflon | Teflon | Black gray | >10 | >16 | ≤260℃ | Resistance to friction, high and low temperature, corrosion, acid and alkali |

| perirelin | Parylene | transparent | 6-12 | >24 | ≤140℃ | It has good electrical insulation, moisture proof, corrosion prevention and salt spray prevention |

Note: The time of salt spray test and PCT test for different products depends on the actual shape

Focus on

Focus on